Tooling

Tooling

WEBSHOP

Svenska Tanso offers the complete range of premium wire edm tooling manufactured by System 3R.

System 3R, a company determined in producing superior quality products & solutions in accuracy, flexibility and productivity.

Founded in 1967 and can rely on more than half a century of knowedge and excellence in this field, System 3R has always been devoted to develop premium products and solutions for the ever increasing demands on high end manufacturers in precision engineering.

Through decades of extensive R&D, in close collaboration with world leading precision manufacturing companies they have developed a unique know-how in precision engineering.

Submicron is their everyday task; repeatability is another, by using their products and services one can achieve benefits from.

- Increased productivity

- Vastly improved quality

- Greater flexibility

Premium products made in Sweden.

Accessories

Accessories

Svenska Tanso has a wide range of accessories and peripherals for EDM.

We stock and sell products as equipment for ion exchange (Pressure vessels) etc., compact reverse osmosis systems (RO ), ultrasonic cleaners, conductivity meters, pH-indicators, tension meters, refractometers, holding magnets (super magnets), fixing foil, cleaning pins, magnifying glasses and loupes, abrasive rubber, picking magnets, LED lights, inspection mirrors, etc.

In short, more or less everything you need for your production.

Chemicals

Chemicals

Svenska Tanso provides a full range of chemicals for wire EDM machines.

We stock and sell products as ion exchange resins, corrosion inhibitors, lubricants, cleaners, degreasers and rust removers.

Svenska Tanso has together with a world leading manufacturer of ion exchange resins developed our own ion exchange resin.

An ion exchange resin tailored specifically for wire edm operations. This ion exchange resin has high capacity over the entire life cycle and also allows for high water flow through our Aqua iQ device, without affecting the quality of the demineralization.

A water conductivity of less than 0.5 micro-Siemens is to be expected. (To some extent depending on the quality of incoming water supply).

In order to facilitate for you and to increase efficiency in your production, we recommend you to join our iQ-Exchange-service. This service means that we send our filled Aqua iQ devices to you and bring back the used unit in order to ensure that all waste is disposed of in an environmentally sound manner.

Less trouble for you and the environment, we promise you that.

Our anti-corrosion agents and lubricants, etc. are produced by Buchem Chemie + Technik GmbH & Co. KG.

Buchem has since more than 30 years in-house manufacturing of specialty chemicals for electro-discharge machining, tool making and injection moulding. A unique know-how has been built up over decades and has been continuously further developed and products adapted to suit the ever-increasing demands for products used in an ever more technologically advanced production.

All areas can benefit from Buchem’s unique know-how, with a comprehensive product range that is specially developed for these areas of production, we offer their products within.

Corrosion protection and lubrication

Rust removal

Cleaning and degreasing

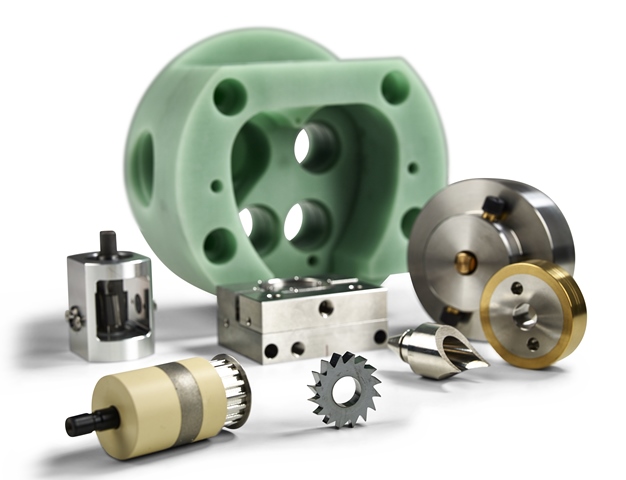

Wear parts

Wear parts

Svenska Tanso has a comprehensive product range of wear and replacement parts for all common manufacturers as:

Agie, AgieCharmilles, Brother, Charmilles, Excetek, Fanuc, GFMS, Hitachi, Japax, Makino, Mitsubishi, Ona, Seibu and Sodick.

High quailty EDM wear parts:

We stock and sell nothing but quality parts and also produce our own, either in-house in our state of the art workshop or through quality-assured and certified subcontractors

All to ensure that you as our customer will get correct quality for your machine and have a production, guaranteed to be free from any downtime caused by poor quality of the replacement parts.

Our complete range of wear and replacement parts is fully compatible with original parts in regards to functionality and appearance.

All of our quality parts obviously have to undergo extensive quality control prior release for sale towards you as our customer.

We offer a complete range of wear parts from our stock: diamond wire guides, power feed contacts, water nozzles to motors, cables and pumps.

We have all parts you may need

OEM parts available

IQ PREMIUM FILTER

IQ PREMIUM FILTER

Svenska Tanso has a comprehensive product line of quality filters for all wire edm machines and applications. We stock and sell filters from several leading manufacturers and also our own developed and highly appreciated top quality product range IQ PREMIUM.

Dirty process water causes instability during the erosion process, such as short circuits and secondary discharges and the result will be defects in the eroded surface, in worst case, a costly piece of scrap metal has been produced, instead of the precision component intended.

In general, the achievable surface finish and final precision is linked to the effectiveness of the filtration system, a cleaner process also provides higher removal rates, better tolerances, more stable conductivity and longer service life on your deionizing system.

This together with reduced wear on your machine.

IQ PREMIUM

FILTERS FOR PURE PROFESSIONALS

ONE MICRON FILTRATION TECHNOLOGY

Our advanced filter series, developed with the latest Japanese technology, offers superior performance and reliability. Crafted with high-density synthetic polyester filter media, these filters combine strength and durability, even in wet conditions, ensuring long-lasting operation with minimal maintenance. The thin structure maximizes the filter surface area, extending the intervals between replacements and reducing your operating costs.

With an absolute filtration accuracy of 1 micron, these filters guarantee exceptionally clean water, protecting your machines from corrosion and reducing the risk of secondary sparking. This results in an improved surface finish, higher cutting speeds, and fewer wire breaks, all contributing to a more efficient and cost-effective production process.

Choose our filtration system and experience the unparalleled quality, durability, and performance that Japanese engineering delivers—an investment that not only extends the lifespan of your equipment but also enhances the quality of your final products.

High pressure stability (>3 Bar) is also ensured.

IQ PREMIUM – The obvious choice

BENEFITS:

- Up to 40 % longer service life by comparison to other high quality synthetic filters

- Extremely pure dielectric from the very beginning of operation throughout the entire process

- Less machine corrosion

- Extended service life of the ion exchange resin

- Reduction of secondary discharge due to fewer particles in the process water

- Improved surface finish

- Higher cutting speeds

- Fewer wire breaks

- Reduced machine wear

EDM wire

EDM wire

Thermocompact SA is our selected main supplier and co-operation partner in this area with technically very complex products. Together with Thermocompact, we have for many years had a very close and fruitful collaboration, together with their research and development department we have made significant progress in the development of new products, and also made great improvements in our mutual customers processes.

As a world leading manufacturer of EDM wire Thermocompact and Svenska Tanso together offer a wide range of high-performance EDM wires, products bringing significant improvements in higher productivity and improved accuracy to users within micro-engineering, precision industry, production edm-ing and general machining.

Thermocompact has been active in this market since 1973 and has ever since continuously developed important innovations that have led to more than 17 product and process patent registrations. The research and development department is currently studying new material structures to achieve even better precision and higher removal rate in order to improve productivity.

Thermocompact has manufacturing facilities in France and in Vietnam with its subsidiary HWA, exporting to more than 50 countries.

- More than 18 product and process world patents

- 2% of the revenues are invested every year in R&D

- Major partnerships with research centres, innovation clusters and global corporations

Svenska Tanso has a comprehensive product range of top quality edm wire.

-

VERY HIGH SPEED & PRECISION

THERMO XCC®

THERMO TEX® -

HIGH SPEED & PRECISION

THERMO SE®

-

SPEED & PRECISION

THERMO SD®

THERMO SD2®

THERMO JP®

THERMO JP2®

THERMO JP+® -

SUPER PRECISION & SPEED

THERMO SA+®

THERMO SA®

THERMO A® -

ALL PURPOSE

THERMO BRASS 1000®

THERMO BRASS 900®

THERMO BRASS 500®

THERMO BRASS 400®

THERMO FIRST 900®

THERMO FIRST 500®

-

ZINC FREE

THERMO ZF®

THERMO ZF+®

THERMO ZF sigma®

Downloadable information